Sheet Metal Fabrication – CAM Software

Integrated CAD/CAM Programming Solutions for Sheet Metal Manufacturing

ALMA

Alma History

35 years of CAD/CAM software to help optimize production. In 1979, Alma was formed: Applied Mathematics Researchers designed the first automated nesting software to save raw materials when cutting textiles, sheet metal, etc. Alma quickly developed in the field of cutting machine piloting software and sheet metal working. In 1996, the Group expanded its activities to off-line robot programming for arc welding and 3D cutting. From Shanghai to Porto Alegre, Alma software is now widely marketed throughout the world and recognized for its optimization capacity and innovative functionality. In 30 years, Alma has become a major CAD/CAM software house, present in many countries.

Alma, a CAD/CAM software company combining innovation and international presence

Known for more than 35 years for our expertise in automated nesting of complex shapes for cutting, we are a leading company in the field of software for sheet metal working, cutting and robotics, and have established ourselves worldwide. Since the beginning, we have designed and developed innovative solutions to optimize material consumption and machine production capacities. We also contribute to the development of emerging technologies by working closely with machine manufacturers. Each year, 20% of Alma’s turnover is reinvested in R&D. Alma offers the most comprehensive range of CAD/CAM software products for all types of cutting, sheet metal working and mechanical welding. This includes in particular: 2D cutting, punching, routing, 5-axis cutting, robotic cutting, tube and profile cutting, shearing, folding/unfolding, robotic arc welding, etc.

Expertise

Known for more than 35 years for our expertise in automated nesting of complex shapes for cutting, we are a leading company in the field of software for sheet metal working, cutting and robotics, and have established ourselves worldwide. Our skills enable us to answer very specialized diverse needs and propose integrated solutions adapted to the various requirements of our customers, whether they use our applicative software, produce machine tools, integrate or edit software. Our core business covering the development and edition of industrial software relies on the following key skills:

- Optimization of industrial processes and algorithmics

- Nesting and CAM applied to cutting

- Sheet metal working CAD/CAM

- Robotics (trajectory calculation, obstacle avoidance)

Address:

ALMA

128, Rue de Silly

92100 BOULOGNE-BILLANCOURT

FRANCE

Contact:

Tel: +33 (0)1 46 99 06 06

Fax: +33 (0)1 46 99 06 07

Email: info@almacam.com

Website: www.almacam.com

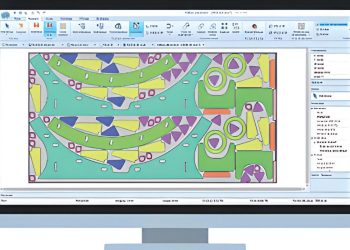

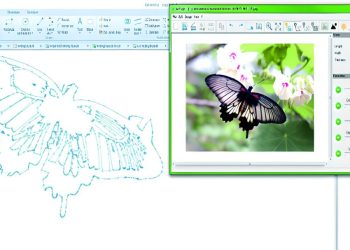

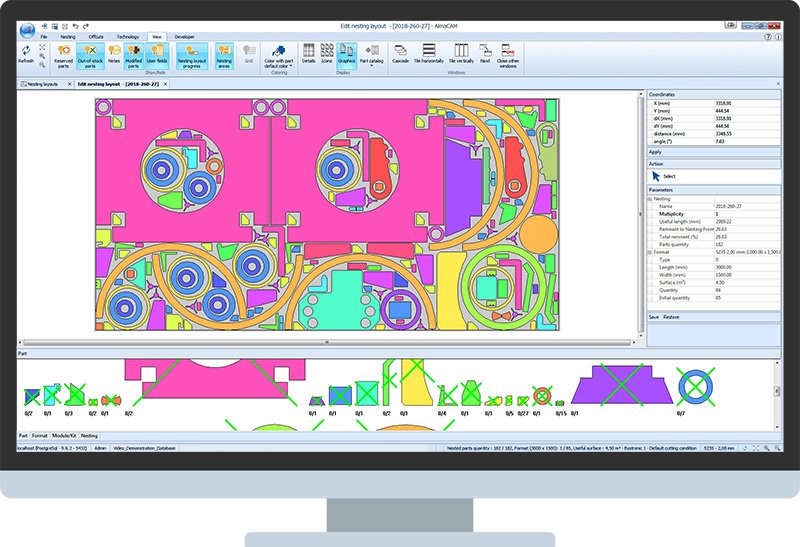

almaCAM Cut

Programming software for 2D cutting

AlmaCAM Cut is a cost-effective yet comprehensive programming solution for 2D cutting machines. It is particularly valued for handling complex contours, importing parts from ERP systems, and its ease of use. Offering excellent value for money, almaCAM Cut is ideal for processing work orders from ERP systems with various machine technologies.

AlmaCAM Cut also stands out for its ability to automatically pre-program all parts, regardless of number or complexity. The software can manage complete batches of parts from one or multiple work orders and automatically produce NC programs.

AlmaCAM Cut is compatible with various machine types including laser cutting, plasma cutting, waterjet cutting, oxy-fuel cutting, as well as punching and punching-routing combination machines.

Key benefits and advantages:

- One-click automatic generation of cutting programs

- Automatic technology creation with tool and technology database

- Multi-part simultaneous programming

- Automatic nesting with powerful optimization algorithms

- Multi-work order management with automatic machine grouping

- Reporting and full production tracking

- Import from ERP and third-party CAD programs

- Tool change optimization and automation

- Smart process management and NC program optimization

- Multiple technology support with automatic common line processing

Gallery

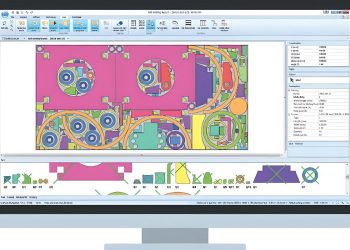

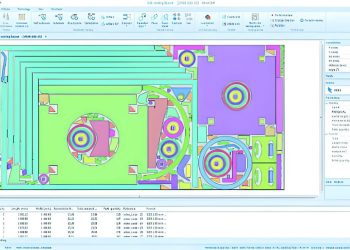

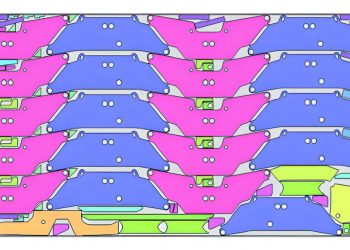

Punching Software

Programming software for punching-nibbling

The AlmaCAM software suite is an integrated programming solution designed for punching-nibbling machines and combination technologies, as well as for routing and continuous 2D cutting. Whatever machine you operate, almaCAM is optimally configured to rationalize your programming process while considering the specificities of each technology or machine.

The added value of almaCAM Punch in punching-nibbling technology lies mainly in powerful software automation (tool allocation, machining sequence, nesting, part evacuation, etc.). This makes almaCAM Punch a highly productive solution for on-demand production of many and varied parts. The software can manage all loading/unloading peripheral systems and is perfectly adapted to combination machines.

Key benefits and advantages:

- One mouse click to perform tool allocation and part nesting, optimize machining sequence including part evacuation and generate CN program

- Automatic completion of common cuts for identical parts with or without micro-junctions

- Automatic part nesting under or around clamps

- Multi-tool and special tool management

- Automatic or manual management of all types of evacuation systems

- Multi-work order management with automatic quality control and part tracking

- Compatible with all peripheral automation systems

- Optimization of all tools and operations across all work orders

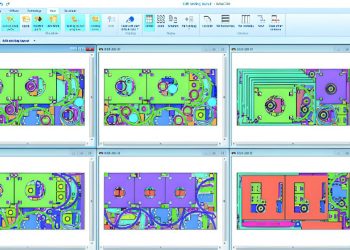

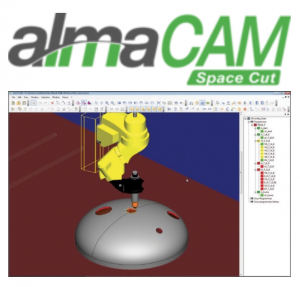

3D Cutting Software

Programming software for 5-axis cutting machines and cutting robots

Thanks to solid CAD/CAM experience in the cutting sector plus machine and robot programming skills, Alma has developed highly efficient solutions for programming 5-axis cutting machines and cutting robots.

Our software solutions are compatible with all types of cutting machines and technologies including laser cutting, waterjet cutting, plasma cutting, and oxy-fuel cutting. The software provides complete solutions from design to NC program production with collision simulation and path optimization.

Key benefits and advantages:

- Support for all 5-axis cutting technologies

- Automatic collision detection and avoidance

- Cutting path optimization

- 3D simulation and verification

- Compatible with various robot brands

- Import from all major CAD formats

- Automatic tool path generation

- Complete NC program optimization

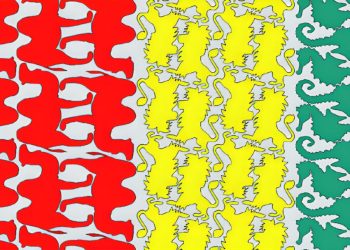

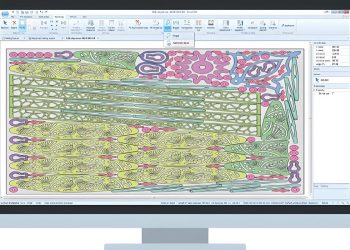

Nesting Software

Software component for automated nesting of complex 2D shapes

Since developing the first software algorithms for automated nesting 35 years ago, Alma has continuously provided leading and innovative nesting software and cutting optimization solutions for industries worldwide. Today, we are a leading provider of 2D and 3D cutting software tools and nesting software components that can be integrated into your existing applications, whatever system or technology you have. Our software provides powerful algorithms and functions for the complete range of cutting and nesting requirements for sheet metal working, packaging, plastics, shipbuilding sector… Alma technology provides unmatched performance solutions for your industry.

Key benefits and advantages:

- Advanced nesting algorithms with maximum material utilization

- Automatic optimization of part placement

- Support for complex shapes and irregular parts

- Multi-sheet nesting with automatic sorting

- Remainder sheet management

- Real-time nesting visualization

- Integration with ERP and CAD systems

- Complete material waste reporting