Deburring Rounding Finishing

Premium Solutions for Deburring, Edge Rounding, and High-Quality Finishing

Timesavers

Timesavers has been setting the standard for years

Timesavers is the world’s largest manufacturer of wide abrasive belt equipment with locations in Minneapolis (USA) and Goes (The Netherlands). More than 50,000 Timesavers wide belt grinding machines have been sold worldwide and most are still in operation today. With over 70 years of experience and a large customer base worldwide, we recognize like no other the needs and strength of constant development and innovation. We provide our customers with a total package of technical solutions, international production, extensive application knowledge and unparalleled after-sales support. All this is carried by a dedicated team with a sharp focus on quality and customer satisfaction.

Creativity and technology go hand in hand at Timesavers

We subscribe to the premise that different options are needed for different applications and no one offers a wider range of machines than Timesavers. In addition, Timesavers also develops and produces machines for special applications up to complete turnkey project solutions with various types of peripheral equipment. Timesavers thinks in terms of solutions and is happy to meet your challenges with passion and enthusiasm.

Your products deserve the best quality

You will have an in-house solution with Timesavers wide abrasive belt equipment for optimal processing of products made of steel, stainless steel, aluminum and coated Zincor (including plastic film or textured surfaces). Are you looking for perfection in deburring, edge rounding, finishing or precision grinding with the highest quality achievable and with an unmatched finish? Choose Timesavers.

Address:

Fruitlaan 20-30

4462 EP Goes

P.O. Box 68

4460 AB Goes

The Netherlands

Tel: +31 113 238911

Fax: +31 113 232003

Website: www.timesaversint.com

42 Series

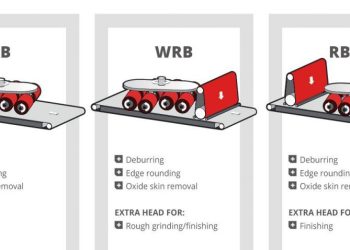

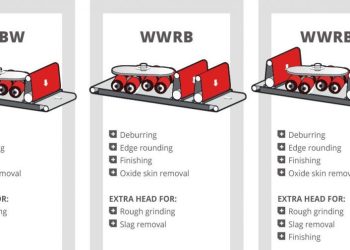

42 RB Series for deburring, finishing, edge rounding and laser oxide removal

Discover the ultimate machine for deburring, edge rounding and perfect finishing of your products. This is Timesavers most popular and award-winning machine.

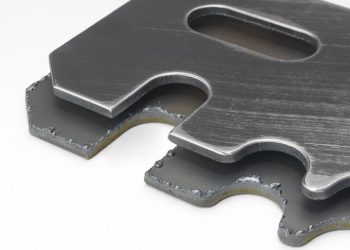

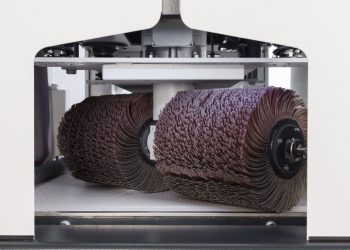

The 42 series offers solutions for manufacturers supplying premium quality products. This best quality is achieved through a multi-rotating brush machine with eight brushes that uniformly deburr and perfectly round metal edges. This ensures you can create rounding radii up to no less than 2 mm.

This deburring machine can also be equipped with one or more abrasive belt heads and will therefore perfectly remove very large burrs and/or will guarantee a perfect finish. The machine is suitable for machining plasma cut, 3D and machined parts. In addition, small parts (from 30 mm) to large parts up to 1600 mm can be machined. Machinable materials include stainless steel, aluminum, zincor, zinc and laser film products.

42 Series Advantages:

- Uniform deburring with 8 rotating brushes

- Edge rounding up to 2 mm radius

- Can be equipped with multiple abrasive belt heads

- Suitable for plasma cut, 3D, and machined parts

- Capacity from 30 mm to 1600 mm

- Materials: stainless steel, aluminum, zincor, zinc, laser film products

- Perfect laser oxide removal

- Premium quality finish

42 Series Gallery

32 Series

Compact dry operation machine for deburring, edge rounding and finishing

The 32 series is a compact dry operation machine for deburring, edge rounding and/or finishing various materials. This machine has the same appearance as the Red Dot Award 2016 winning design of the 42 RB series.

This machine forms a new standard in deburring, edge rounding and finishing technology for various materials. This compact machine can be equipped with the recently developed Timesavers attachment: rotary brush.

Much attention has been paid to ease of use and user comfort regarding this stylish and efficient deburring and finishing machine. The result is a machine that can be operated intuitively and easily. In addition, low consumable use, energy-efficient machine and optimal price-quality ratio. The machining process can be easily observed due to the tilted control panel and large windows.

32 Series Advantages:

- Compact and efficient design

- Red Dot Award 2016 winning design

- Equipped with rotary brush attachment

- Intuitive and easy operation

- Low consumable use

- Energy efficient

- Optimal price-quality ratio

- Tilted control panel for easy observation

- Large windows for process monitoring

32 Series Gallery