Arku

ARKU has been working with sheet metal since 1928 and has become the European market leader in leveling and feed equipment. Our headquarters are located in Baden-Baden. In the center of the Technologie Region Karlsruhe, we produce leveling machines and turnkey coil lines.

ARKU offers a wide range of levelers. From precision levelers for parts and sheets to high-capacity levelers for coiled material. ARKU levelers are integrated into turnkey press feed systems, coil preparation lines for roll forming, and cut-to-length lines. Thousands of ARKU levelers are used worldwide and we have become the market leader in leveling and coil feed equipment.

With ARKU leveling centers in Baden-Baden, Cincinnati and Kunshan, as well as a large network of representatives, we offer special services to our customers. We enable them to perform leveling tests with their own material on our various leveling machines. In addition, we offer contract leveling services for everyone.

Address:

Siemensstraße 11 | 76532 Baden-Baden

Germany

Tel: +49 7221 / 5009-0

Fax: +49 7221 / 5009-11

Website: www.arku.com

Leveler

EcoMaster® Precision Leveler

For metal sheet components with thickness from 0.3 mm to 5 mm

The EcoMaster® precision leveler series provides consistently high-quality leveling results, especially when working with smaller and thinner components. Flat and stress-free parts help subsequent processes work better. EcoMaster® is easy to operate and maintain, making operations more efficient.

Application in Aerospace Industry

The AeroSpace EcoMaster® design is specifically developed for leveling components in the aerospace industry. High-strength and lightweight materials need to be processed under cold conditions. Important machine components can experience corrosion on levelers with overly simple designs.

In EcoMaster®, vulnerable components are protected against corrosion so the machine can provide stable and reliable leveling results.

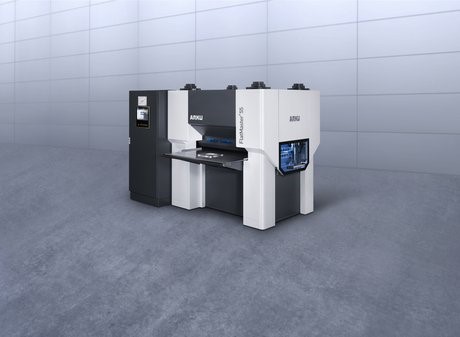

FlatMaster®

For metal sheets with thickness from 0.5 mm to 60 mm

FlatMaster® is a hydraulic precision leveler resulting from more than 40 years of experience in making leveling machines.

The leveling process with FlatMaster® is fast and simple. Compared to other methods, FlatMaster® produces flat and almost stress-free parts from punching, laser-cut, and flame-cut processes in just minutes, making subsequent processes like welding or bending faster and more reliable.

Special Features

- Leveling gap control

Provides consistent leveling results even on components with holes/cut-outs. - Quick-change roller system

Comprehensive maintenance and cleaning can be done quickly and easily. - Overload protection

Before excessive force is reached, the machine will stop and the leveling unit will lift. - Intuitive control

Easy-to-use digital control screen with job setting database and recommended values.

PlateMaster®

For large plates and sheets with thickness from 4 mm to 80 mm

PlateMaster® is designed to economically level large sheets (width up to 3,000 mm) and thick plates. This hydraulic leveler is specifically made for heavy plate fabricator needs.

PlateMaster® has a design that is deliberately made simpler and more economical. The machine is designed for heavy working conditions, is not easily affected by dirt, and is easy to clean.

Special Features:

- Specifically for large sheets and plates

- Robust and not easily affected by dirt Designed for heavy working conditions.

- Easy to level rusty and dirty parts Efficient cleaning system.

- Quick and easy leveling unit cleaning Quick access design for maintenance.

- Consistent leveling results Thanks to servo-hydraulic leveling gap control.

- Hydraulic overload protection Safety system to protect the machine.